Peloni: Bryen presents a very important analysis of the effort to solve US dependence on foreign chip producers which he argues will only serve to produce more expensive, less quality chips at the hands of foreigners. The fundamentals in the US need to be addressed to address this problem, and that begins with the catastrophic crisis in US education. Without first addressing this sizeably related problem, any attempt to solve the US dependence on foreign sources of chips will struggle with the consequences of not having done so.

The Intel Debacle Proves the Commerce Department handed out money uncritically

Stephen Bryen | Weapons and Strategy | August 4, 2024

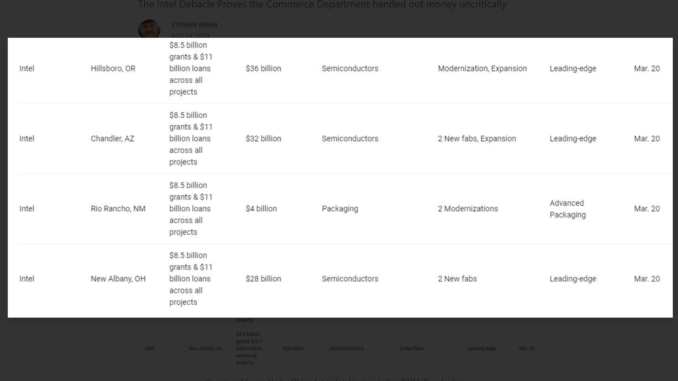

Grants and Loans Under Chips Act to Intel (not including $3.9 billion for Secure Enclaves)

Grants and Loans Under Chips Act to Intel (not including $3.9 billion for Secure Enclaves)

While all the focus in the past week has been on a significant crisis for America’s once premier semiconductor company, Intel, hidden from view is another blunder –a $3.9 billion project to build a “secure enclave” semiconductor manufacturing facility. Intel will probably locate this facility in Arizona, where it already has a semiconductor FAB.

If you are about to ask what will be produced at this facility, don’t bother since the project is classified. But even though the details are hidden, it isn’t hard to figure out what is going on and why it is a big mistake (like the CHIPS Act itself, a $59 billion dollar investment that will mostly finance foreign and domestically owned companies to set up facilities in the US). Because the CHIPS Act is a bipartisan waste of money, only the poor taxpayer will (once again) be robbed.

Some of the foreign companies financed under the CHIPS Act are: Samsung (Korea), TSMC (Taiwan), Global Foundries (UAE), BAE Systems (UK), Global Wafers (Taiwan) and Amcor (Australia). All these companies are awash in money, so the added US money is not needed.

The Secure Enclave project is based on a single intelligence report that, like the project itself, is classified. However, the gist of the intel-report is that an adversary could get into a semiconductor manufacturing plant (a FAB) and somehow insert bad code into the chip manufacturing process, aka spyware. There is absolutely no proof that any commercially produced chip has ever been compromised, but that didn’t stop the CIA from claiming something like this could happen. In effect we are betting billions of dollars on poor intelligence with no empirical evidence to support it.

For some time some in the Pentagon and the intelligence establishment have been dreaming about the need to fully vet microchips. Since most chips in US military and intelligence systems come from Asia, it is understandable such a concern would arise. It was fueled by some Chinese routers and other gadgets including surveillance cameras that were found to have backdoors that gave the Chinese an ability to spy on military, intelligence and government operations.

The easy solution would be for the government to buy only made in America products with made in America chips. What would seem to be common sense did not appeal to government buyers. They doubled down buying more and more equipment either chock full of Chinese-made parts, or even worse, just buying Chinese products off the shelf. A good example are surveillance cameras. After it was amply demonstrated that cheap cameras made in China had backdoors, the military went out and either bought more for base security and other applications, or they avoided getting rid of the compromised products, even after they were ordered to do so.

The Secure Enclave is supposed to prevent anyone compromising chips made for military and intelligence applications. This means that the factory will have strong security. This presents a significant problem because many of the workers in the US semiconductor industry come from abroad, either from India, Pakistan, or Asia (including China). The Semiconductor Industries Association says that the CHIPS Act (not counting Secure Enclaves) will require 115,000 new workers by 2030. “Meeting these ambitious numbers will require companies to ramp up hiring significantly in the sector. Many of these roles will require a two- or four-year degree in engineering or computer science. Early research has indicated there are simply not enough U.S. students in the pipeline. Therefore, many companies likely will need to turn to foreign nationals and recruit and retain international students to bridge the hiring gap,” says one report. One out of every five jobs will likely be filled with STEM qualified foreigners (science, technology, engineering, and mathematics), maybe more.

The Secure Enclave cannot use foreign workers if the facility is classified. Finding US citizens with the skills needed in a competitive and short-staffed environment to work in a dead-end factory in Arizona may be the Achilles heel of the Secure Enclave program. (US Defense companies also are facing hiring shortfalls. Can anyone seriously imagine signage at a Yankees game promoting jobs to build submarines?)

\Assuming the money is used to actually build a secure facility, it will be a very low volume producer of specialized components. This means the cost per chip will be astronomical. The CHIPS money in no way fixes that problem. This means the cost of weapons will soar completely out of control (and it is bordering that already because defense goods are vastly overpriced and less and less affordable even for “rich” countries).

There are other problems too. A specialized factory will not be competing with the commercial sector, so its products are likely to fall well behind the state of the art and do so very quickly. This means that the Secure Enclave will over time manufacture obsolete and overpriced junk.

But it gets worse. Nothing is for free. To keep Secure Enclave viable, the government will need to convince the Enclave’s customers to buy overpriced and inferior secure products. Why would any defense company pay obscene prices for parts it can buy commercially at a fraction of the cost? And why would it opt to put inferior parts in its equipment?

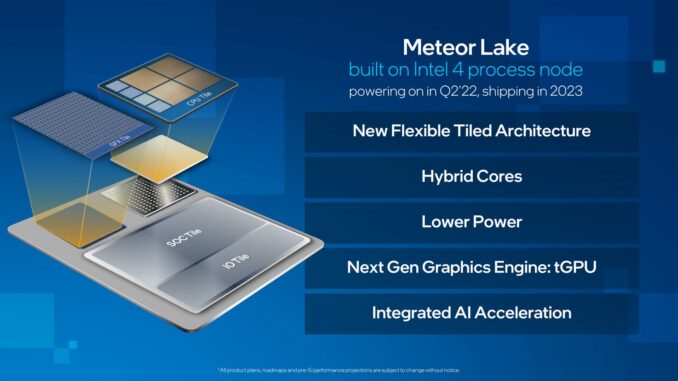

Intel has recently developed a couple of new processors that incorporate an artificial intelligence engine. The idea is to equip a new generation of PCs (personal computers) with built in AI. The first new product is called Meteor Lake. Intel is manufacturing the chip at its plant in Ireland, not in the United States. According to reports, Intel is having trouble making the chip and is losing billions of dollars. So much so that its superior follow-on chip, called Lunar Lake, also has been outsourced, but this time to Taiwan Semiconductor (TSMC). Intel can’t make it and won’t.

Intel’s stock is in the tank, the company has stopped paying dividends, and it is laying off 15,000 workers. Intel was supposed to be adding 10,000 new jobs as part of the money it was getting from the government’s CHIP’s Act, so it isn’t unfair to say that thanks to the problems facing the company and the lack of any serious corporate vetting by the Department of Commerce, which is handing out CHIPS money, the US will lose a net of 25,000 jobs and Intel’s products will need to be outsourced for the company to survive.

Intel’s saga is likely to be repeated by many other semiconductor companies who are getting handouts under the CHIP’s Act. There is no guarantee any of them will end up being competitive. Many of the foreign companies are excessively rich: so the CHIPS Act is just a bribe for them to locate manufacturing in the US. Many of them, including TSMC, are not going to bring state of the art production to the US for two reasons: they will want to keep their best technology under their firm control and not risk losing it in the United States; TSMC will want to keep its market access free from US export controls. Why risk your business for a monetary handout you don’t need?

None of this is to say that some good may come out of the $59 billion CHIPS Act investment. But if the idea is to create a domestic manufacturing base by throwing money at foreign and domestic companies, think again.

Leave a Reply

You must be logged in to post a comment.