A visit to the country’s largest desalination and wastewater-treatment plants reveals smart technologies and policies to keep the water running

By Abigail Klein Leichman, ISRAEL 21c JANUARY 6, 2019,

Israel has solved its water crisis! That’s a typical headline about Israel’s world-leading smart water management and advanced water technology.

As I sipped freshly desalinated Mediterranean water at the world’s largest seawater desalination plant, the brilliance of Israel’s many-pronged approach was as clear as the H2O in my paper cup.

But if residents, farmers and tourists in the Holy Land never worry about the tap running dry, that’s only because Israel invests huge amounts of money and brainpower to stay one step ahead of a worsening worldwide water crisis.

Five years into a severe drought, it’s more accurate to say that Israel is constantly inventing and implementing practical solutions to a problem that is not entirely solvable.

“It is a never-ending story,” says Yossi Yaacoby, chief of staff to the CEO of Mekorot, Israel’s national water carrier. Yaacoby formerly headed WaTech, Mekorot’s innovation arm.

Due to climate change, he explains, Israel’s October-to-March rainy season has been reduced to a handful of torrentially rainy days, causing most of the precious liquid to be lost to runoff. The North’s waterways are no longer an abundant trickle-down source for much of the country; the Sea of Galilee is approaching its lowest-ever level.

“This is why we can’t depend on rain. Even in winter we need to irrigate. And it’s not only in Israel; it is happening everywhere,” says Yaacoby.

Since 2005, wastewater reclamation and seawater desalination have become key in assuring an adequate supply — 2.1 billion cubic meters annually — to Israeli households, industry and agriculture.

Some 31 percent of irrigation water originates from wastewater treated at more than 150 plants. Treated brackish water (not as salty as seawater) is supplied from 45 plants for both agricultural and non-agricultural needs.

Sixty to 80% of Israel’s municipal water, adjusted according to season and real-time demand, flows from large coastal desal plants in Sorek, Ashkelon, Ashdod, Palmachim and Hadera.

“In 2014, we thought we had enough [desalinated water] capacity, 600 million cubic meters, that it didn’t matter how much [rain] God will supply in the winter,” says Yaacoby. “That was a mistake. We are lacking 100 million to 200 million cubic meters of water per year in Israel these days.”

Two more desalination plants are to be completed in the next few years. “Altogether, in 2025 we will be getting 1.1 billion cubic meters of desalinated water,” Yaacoby says.

Sorek, world’s largest desal plant

Operational since 2013, Sorek is the largest seawater reverse osmosis desalination plant in the world. It is operated for the government by water-treatment pioneer IDE Technologies, established in 1965 by Technion-trained scientists.

IDE is now a multinational company with 400 desal and wastewater treatment installations in more than 40 countries.

The highly automated Sorek plant covers 100,000 square meters and can produce 624,000 cubic meters of water daily — 20% of domestic water consumption.

Mekorot distributes the desalinated, quality-tested water (after essential minerals have been re-added) to 57 municipal water utilities throughout Israel. From Sorek, it costs about 55 cents per cubic meter; somewhat more from the other four plants.

By comparison, it costs 10 cents to get a cubic meter of freshwater from Israel’s natural sources – whose supply is fast declining. In some other countries, desalinated water costs as much as $3 per cubic meter.

IDE developed proprietary technologies to minimize costs and environmental impact, says Boris Liberman, CTO and VP of Membrane Technology.

Desalination normally uses chemicals, which present an environmental problem when the brine is discharged back to the sea. IDE uses chemical-free biological and physical processes customized for each installation.

“We use biological filters to remove bacteria, silt, algae and other suspended solids. We don’t kill anything, even bacteria,” says Liberman.

To avoid harming the little fish and fish eggs that pass through the screens on the intake pipes bringing in 40,000 cubic meters of seawater per hour, IDE is developing “nursery” tanks where the creatures are harbored until they choose to swim back to their habitat via rotating doors.

As for the plant’s effect on the Mediterranean, “What we pump back into the sea is twice as saline and one degree warmer than seawater,” says Liberman. “We use diffusers to spread it widely. We don’t believe it negatively affects marine life.”

Desalinating about 500 liters requires 1.5 kilowatts of electricity, similar to the power consumption of a refrigerator, Liberman says. Sorek therefore produces most of its water at night to avoid straining the national grid. Each plant has a different energy source; some have their own power stations.

Wastewater reclamation

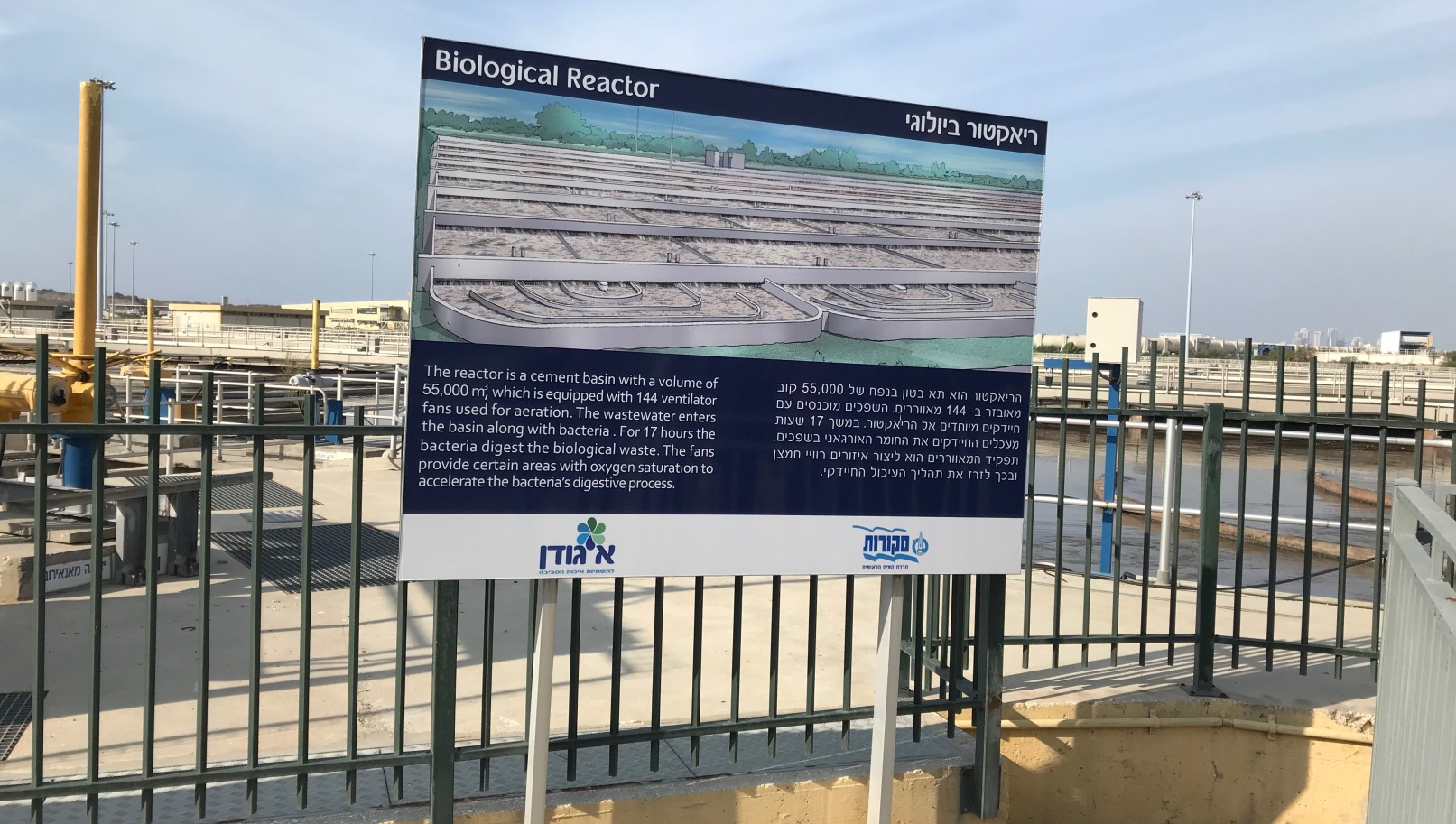

Covering 250 acres, Shafdan is the biggest wastewater treatment plant in a country that recycles more water (85-90%) than anywhere else. The reclaimed water, which Yaacoby says is close to drinking quality, is pumped to Negev farms for irrigation.

“Shafdan uses biological and mechanical means to treat all sewage effluent from the Dan (Greater Tel Aviv) region, home to approximately 250,000 to 300,000 people,” Yaacoby explains during a tour of the plant, one of the most advanced of its kind in the world.

Shafdan, established in 1955, receives 470,000 cubic meters of raw sewage daily. Reclaiming the water from this sewage supplies 140 million cubic meters to Israeli farms annually just from this one facility.

Like desalination, wastewater reclamation is energy-intensive. (Mekorot is the biggest client of the Israel Electric Company, racking up a $200 million bill annually, says Yaacoby.)

However, over the past two years at Shafdan, enough biogas has been generated onsite from the anaerobically treated sludge to provide 90% of the facility’s energy needs.

“We don’t even call sludge ‘waste’ anymore because it is a resource from which to make energy, bioplastics and fertilizer,” Yaacoby says.

Clouds and leaks

Mekorot’s WaTech runs several R&D centers that collaborate with industry and academia – and funders including the European Union’s Horizon 2020 program – to fill unmet needs in water resources management, wastewater treatment and quality, and digital solutions.

One of these centers is at Shafdan, where there is an urgent need for more compact treatment methods in order to free up some of the valuable real estate on which the plant sits. A variety of pilot projects will determine the best path forward.

Yaacoby says cloud seeding was once thought a promising procedure for squeezing more rain from the skies. But experiments have been disappointing so far. Right now there is only one small cloud-seeding experiment over the Sea of Galilee.

That sea – actually a lake, called the Kinneret in Hebrew — today supplies a mere 50 million cubic meters of water to area villages in Israel and 50 million to Jordan every year. “We have a new plan to take desalinated seawater from the new plants to enrich the Sea of Galilee by 2030,” Yaacoby says.

More helpful in boosting available water supply is Israel’s exceptionally low rate of leakage, he adds. In most countries, an average of 30% of expensive treated water is lost through leakage before reaching customers.

“Israel’s leakage rate is lowest in the world, on average 7-8%,” says Yaacoby. This is partly because Israel’s distribution infrastructure is relatively young and isn’t subject to extreme temperature fluctuations that can burst pipes.

The Israeli startup Utilis is revolutionizing leak detection, using satellite-mounted radar — developed originally to find water on Mars and Venus — to map out where drinking water is escaping from the system. Since 2016, Utilis technology has been employed in 27 countries including China, US and UK.

Utilis is one of about 300 Israeli water-tech companies bringing new solutions for everything from precision irrigation to municipal water management. And the academic water-research sector, notably Ben-Gurion University of the Negev’s Zuckerberg Institute for Water Research, collaborates with many private institutes and governmental bodies worldwide.

Assuring a wet future

While Israeli knowhow and technology have a well-deserved place in the world spotlight, conservation and awareness are critically important in assuring adequate and affordable water, emphasizes Oded Distel, director of Israel NewTech in the Ministry of Economy and Industry.

“Whatever we eat or wear is tightly connected to water consumption,” he says. “Every cup of coffee takes 130 liters to produce from the phase of growing the beans to our cup. A pair of jeans takes 1,320 liters. One kilogram of steak takes 15,400 liters.”

Urbanization, population growth, climate change and increased standards of living are overburdening the shaky – in many places, broken — global water infrastructure, Distel says.

The coming generation will only have enough access to safe water if countries stop wasteful practices like flood irrigation, get leakage under control, and incentivize conservation by charging consumers the actual cost of water.

“People have long expected to get water for free, and that is a big obstacle to building sustainable systems and leads to people not getting any water or low-quality water. When people pay for something it has a value and they are motivated to use it more efficiently.”

Distel believes Israel can serve as a role model for its reliable, sustainable, centralized water system in an arid land where there is no private ownership of water and everyone gets a monthly water bill.

“The outcome is that wherever you are in Israel, when you open the tap you get high-quality drinking water, which is not something that happens everywhere in the world,” Distel says.

Click here to find out about WaterLine, Israel NewTech’s English-language podcast dealing with water issues in the global arena.

Leave a Reply

You must be logged in to post a comment.